Advanced production systems (APS) program is one track of the Master of Science, untitled Knowledge Integration in Mechanical Production.

Campus

Arts et Métiers campus of Lille

Objectifs

Design and integrate agile (flexible and rapid) production systems for modern and competitive production industries.

Learning outcomes

Identifying and formalizing the Knowledge based on a scientific approach about Modeling, and designing of advanced production systems. The KIMP-APS program provides training for further PhD studies, research activities or positions in industry as an expert with having an international experience by working in an international and multicultural context.

Program description

This program is composed by one semester of courses taught in English and held in the campus of Lille and one semester dedicated to carry out the Master Thesis. This master thesis is a full time work in a laboratory or in a company, in France or abroad.

The first semester is split into two quarters, one quarter of core courses (shared with all KIMP tracks) and one quarter of specialized courses.

- Fall Semester : Courses.

- Spring Semester: Master Thesis.

Core courses :

- Methods, models for the integration of both product and manufacturing process parameters

- Tools for integration Example on the generation of Machining process by using AI approaches (expert system, Constraint Satisfaction Problem, Fuzzy Logic, AHP)

- Modeling and control of mechatronics devices

- Manufacturing process management

- Literature Review

- French language and culture (Foreign language for French speakers)

Specialized Courses :

- Modeling and Analysis of Dynamic Mechanical Systems

- Control of Dynamic Systems

- Advanced Mechatronics

- Robotics

- Team Building and Management

We use RoboDK for offline simulation and programming of industrial robots.

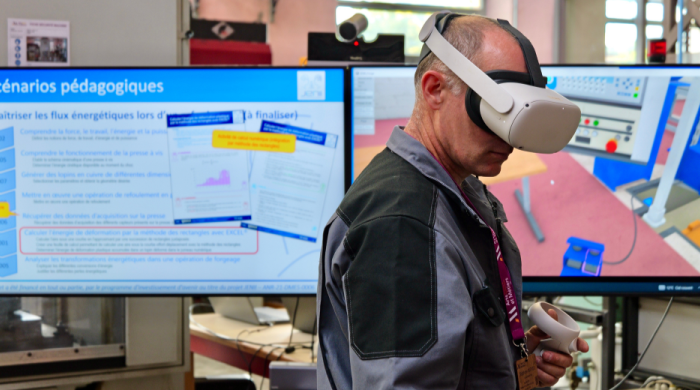

Laboratory and technologic platform

All informations available on LISPEN's Youtube channel

Partners

- University of Teheran (Iran)

- ENSAM Meknès and ENSAM Casablanca

- École Nationale d'Ingénieurs de Bizerte (ENIB)

Internships and projects

Contribution to the creation of the Digital Twin of robotic work station in an assembly line

- Design of Collaborative Robotic Cell for the Assembly of Car Engines.

- Design of a Mixing and Printing Head for the Continuous Bioprinting of Hydrogels

- Nonlinear vibration of a cyclic symmetric structure Implementation of Machine Learning Algorithms for Solving SLAM Problem of Mobile Robots

- Supply chain integration and its effect on both the performance of the supply chain and the quality of the product

- Data Mining on SCADA Event Codes for Predictive Maintenance of Wind Turbines

Practical Informations

- Expected degree: For Arts et Métiers students: the selection is performed through 2A and 2B selection processes. For foreign students: having a degree equals to M1 (first year of Master of science degree)

- Teaching language: English

- Period: One year (starts with fall semester in October)

- Teaching hours: about 200 hours of face to face classes

- ECTS credits: 30 per semester (a total of 60 credits)

Contacts

Key words

#Industry40 #KnowledgeIntegration #MechanicalEngineering #riskAnalysis #IndustrialRobotics #MachineLearning #Mach

If you are applying for the first time and do not have an account ⇒ register online to receive a password to apply

If you have an account ⇒ go to the online application portal